⏳Limited Sale 50% OFF🔥SolderStick wire connector🔗

🚢 Free shipping + Cash on delivery 🚚

What Aerospace Engineers Use When Failure Isn't an Option - Now in Your Garage

Discover the Military-Grade Connector That Creates Bonds Stronger Than Factory Wiring. Without Tools, Without Mess, Without Failure

7,491 Ratings

7,491 Ratings By Mike Jacobs

By Mike Jacobs  Automotive & Marine DIY | August 3rd, 2025| 9:17 am EDT

Automotive & Marine DIY | August 3rd, 2025| 9:17 am EDT

I've been fixing things with my hands for over 30 years.

Cars, boats, trailers, RVs - if it had wires, I could make it work. Hell, I was the guy my neighbors called at 9 PM when their truck wouldn't start. The one my buddies trusted to rewire their entire boat electrical systems.

I built my reputation on being the mechanic who got it right the first time.

So when my trailer lights died for the THIRD time in two months—lights I had "permanently" fixed using every trick I knew—something inside me snapped.

This wasn't just about trailer lights anymore. This was about my identity as a craftsman being slowly destroyed by connections that looked perfect but failed when it mattered most.

Standing there in the AutoZone parking lot, staring at another pack of crimp connectors, I finally asked the question that changed everything:

"What if the problem isn't my technique... what if it's the method itself?"

The Brutal Truth About Why "Professional" Wiring Methods Fail

Here's what 30 years of electrical work taught me the hard way:

Every single "standard" connection method is designed to fail.

Think about it. Crimp connectors rely on mechanical pressure to hold wires together. But what happens when that connection gets hit with constant vibration from a trailer bouncing down the highway? The metal fatigues. The pressure loosens. The connection dies.

Electrical tape? It's literally designed as a temporary solution. The adhesive breaks down from heat. Moisture seeps through microscopic gaps. UV rays make it brittle and crack.

Even hand-soldering—which most of us consider the "gold standard"—has a fatal flaw. Solder creates a rigid joint in a flexible wire. Every time that wire moves, stress concentrates at the edge of the solder joint until the copper work-hardens and snaps.

We've been using Stone Age technology to solve Space Age problems.

But here's the kicker: While we've been struggling with these doomed-to-fail methods, there's been a completely different approach hiding in plain sight.

The Military Secret That Changes Everything

Back in the 1940s, engineers working on critical field operations faced a challenge: how to create reliable electrical connections without bulky tools or open flames.

To solve it, they developed a heat-activated connector that could form a secure bond in seconds - without the need for soldering irons or complicated equipment.

The results were so effective that this technology was reserved for aerospace and military applications for decades. It’s been used in everything from fighter jets to deep-space systems - places where reliability isn't optional.

But in recent years, manufacturing innovations have made it possible to bring this advanced connection method to everyday mechanics and DIYers.

That breakthrough is now available to the public under the name SolderStick - a tool-free, heat-activated connector that forms a strong, sealed connection in just seconds.

How SolderStick Eliminates Every Failure Point

Here's why SolderStick connections don't just work better—they work differently.

Instead of fighting against physics, SolderStick harnesses it.

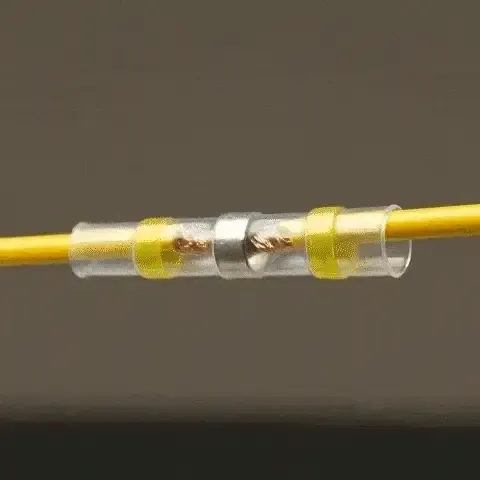

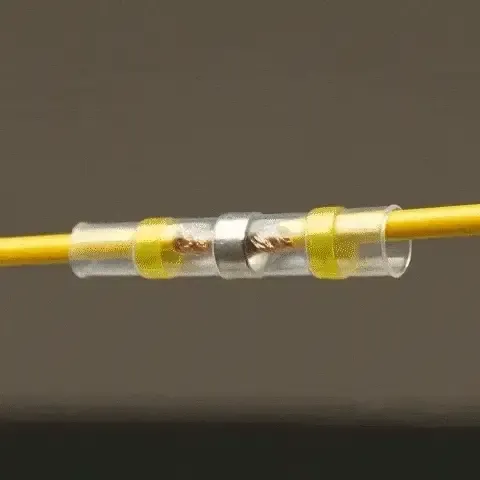

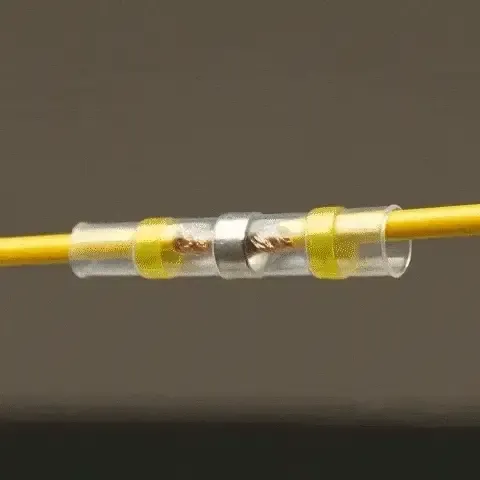

Each connector contains a precisely engineered ring of low-temperature, high-strength solder alloy - the same formula used in aerospace applications. This isn't the weak, lead-based solder from your grandfather's toolbox. This is a proprietary blend that flows at just 280°F but creates bonds stronger than the wire itself.

Surrounding that solder ring is dual-wall, military-grade polyolefin tubing lined with industrial adhesive. When heated, this creates a hermetic seal that's rated IP67 waterproof - the same standard used for submarine electrical systems.

The process is almost stupidly simple:

1️⃣ Strip your wires and insert them into the connector

2️⃣ Apply heat with any heat source (heat gun, torch, even a hair dryer)

3️⃣ Watch 70 years of military engineering work its magic

In seconds, three things happen simultaneously:

The solder melts and flows through every strand of wire, creating a molecular bond. The inner adhesive activates, forming a waterproof barrier. The outer tubing shrinks down, creating a vibration-proof shell that actually gets stronger under stress.

The result? A connection that's literally more reliable than factory wiring.

I Put SolderStick Through Hell - Here's What Happened

When my SolderStick kit arrived, I'll be honest - I was skeptical as hell.

After three decades of being burned by "revolutionary" products that promised everything and delivered nothing, I'd learned to keep my expectations low.

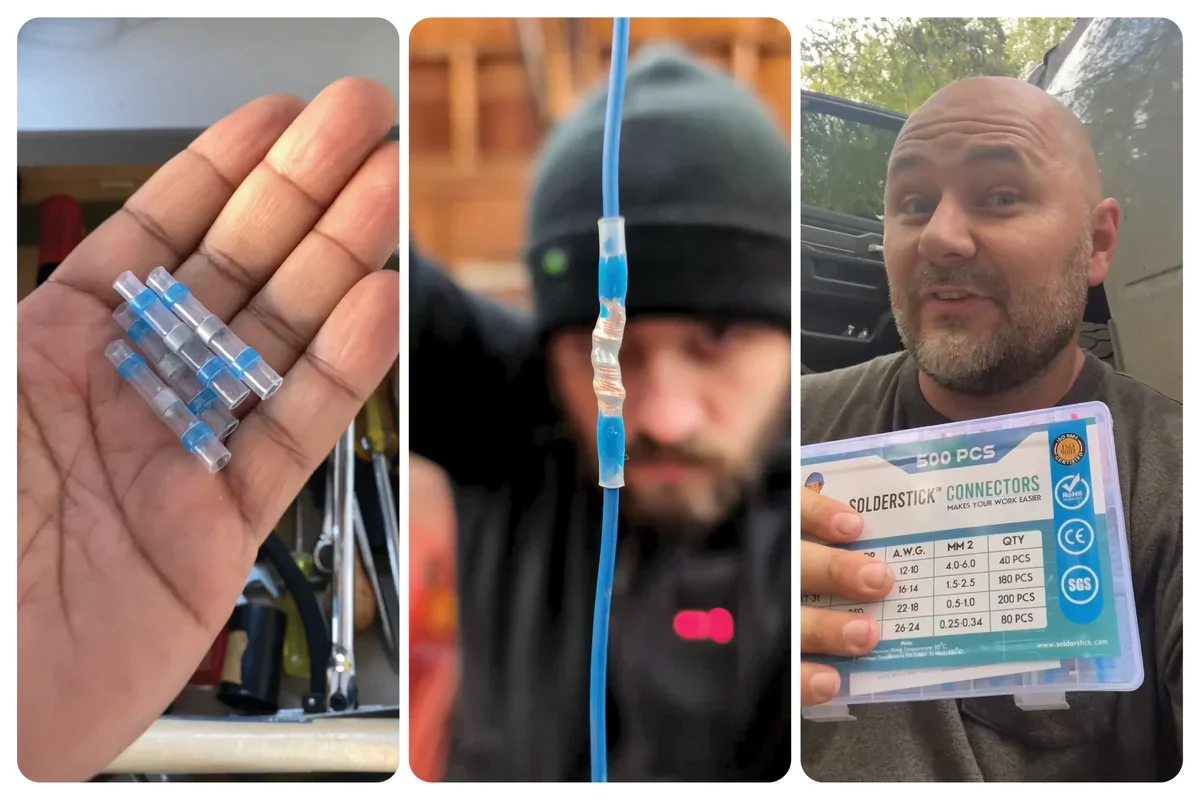

But the moment I opened the package, I knew this was different.

These weren't the cheap plastic sleeves you find at hardware stores. The build quality was immediately obvious - thick-walled tubing, precision-engineered solder rings, military-spec materials throughout.

Still, I needed proof.

So I designed what I call "The Torture Test" - a side-by-side comparison that would push each connection method to its absolute breaking point.

I took three identical pieces of 12-gauge wire and created three different connections:

Connection A: Premium crimp connector with marine-grade heat shrink (my previous "best" method)

Connection B: Hand-soldered joint with professional flux and heat shrink (the "gold standard")

Connection C: SolderStick connector

Then I got ruthless.

Test 1: Salt Water Immersion

I submerged all three connections in salt water for 48 hours—simulating years of marine exposure.

Connection A showed corrosion around the crimp within 12 hours. Connection B held up better but developed a green patina where moisture seeped past the heat shrink.

Connection C? Bone dry inside. Perfect continuity. Zero corrosion.

Test 2: Pull Strength

Using a digital scale, I pulled on each connection until something gave way.

Connection A failed at 22 pounds when the crimp let go.

Connection B held until 31 pounds before the wire snapped at the solder joint.

Connection C? I stopped pulling at 67 pounds because I was afraid of damaging my test equipment.

But the real test came two weeks later...

The Moment That Restored My Pride

It was another Saturday morning boat launch - the same ramp where my trailer lights had humiliated me just a month before.

As I backed down that ramp, my heart was pounding. Not from fear this time, but from anticipation.

I hit the brakes. Brake lights blazed bright red.

Turn signal. Perfect amber flash.

Running lights. Every bulb glowed steady and strong.

But here's what really got me: As I was loading the boat back onto the trailer, another guy walked over. His trailer lights were flickering, and he'd noticed mine working flawlessly.

"Hey, what kind of connections are you using?" he asked. "Mine keep failing every few months."

For the first time in months, I felt that familiar surge of pride.

"Military-grade connectors," I told him, pulling out my SolderStick kit. "Same technology they use in fighter jets."

His eyes widened. "No kidding? Where do you get those?"

That's when I knew SolderStick had given me something more valuable than reliable connections.

It had restored my reputation as the guy who knows how to do things right.

Why Thousands of DIY Mechanics Are Switching to SolderStick

Because once you experience the confidence that comes from knowing your connections will never fail, you can't go back to crossing your fingers and hoping for the best.

WARNING: SolderStick Is Rapidly Selling Out Nationwide

Ever since word got out about this military-inspired connector technology, demand has exploded beyond anything the manufacturers anticipated.

DIY mechanics, marine technicians, RV enthusiasts, and automotive professionals everywhere are ditching their old connectors and switching to SolderStick. The result? Unprecedented demand that's creating nationwide shortages.

Right now, the manufacturers are struggling to keep up. Every time they release a new production batch, it disappears within days - sometimes hours.

And here's the problem: The military contracts come first.

That means when current inventory sells out, it could be months before more becomes available.

Don't Let Another Wiring Failure Destroy Your Reputation

I want you to imagine something for a moment.

Picture yourself six months from now, still using the same old crimp connectors and electrical tape. Still dealing with the same intermittent failures. Still making excuses when your "permanent" repairs let you down at the worst possible moment.

How will that feel?

Now imagine the alternative.

Picture yourself with a toolbox full of SolderStick connectors. Every connection you make is stronger than factory wiring. Every repair you complete stays fixed—not for months, but for years. Maybe decades.

Picture the look of respect in people's eyes when they see your work.

Picture never again having to make excuses for a failed connection. Never again feeling that sick embarrassment when your "professional" repair falls apart in front of others.

Picture being known as the guy who does things right the first time.

That's not just a fantasy. That's exactly what SolderStick delivers.

But only if you act before they sell out again.

Here's How to Get Your SolderStick Connectors Today- At a Massive Discount

Normally, military-grade connectors like these would cost you hundreds of dollars. When aerospace contractors buy these same connectors for fighter jets and satellites, they pay $15-20 per connector.

But the team behind SolderStick made a decision: They want this technology in the hands of every serious DIY mechanic in America.

So they're offering their complete SolderStick kits at a fraction of military pricing:

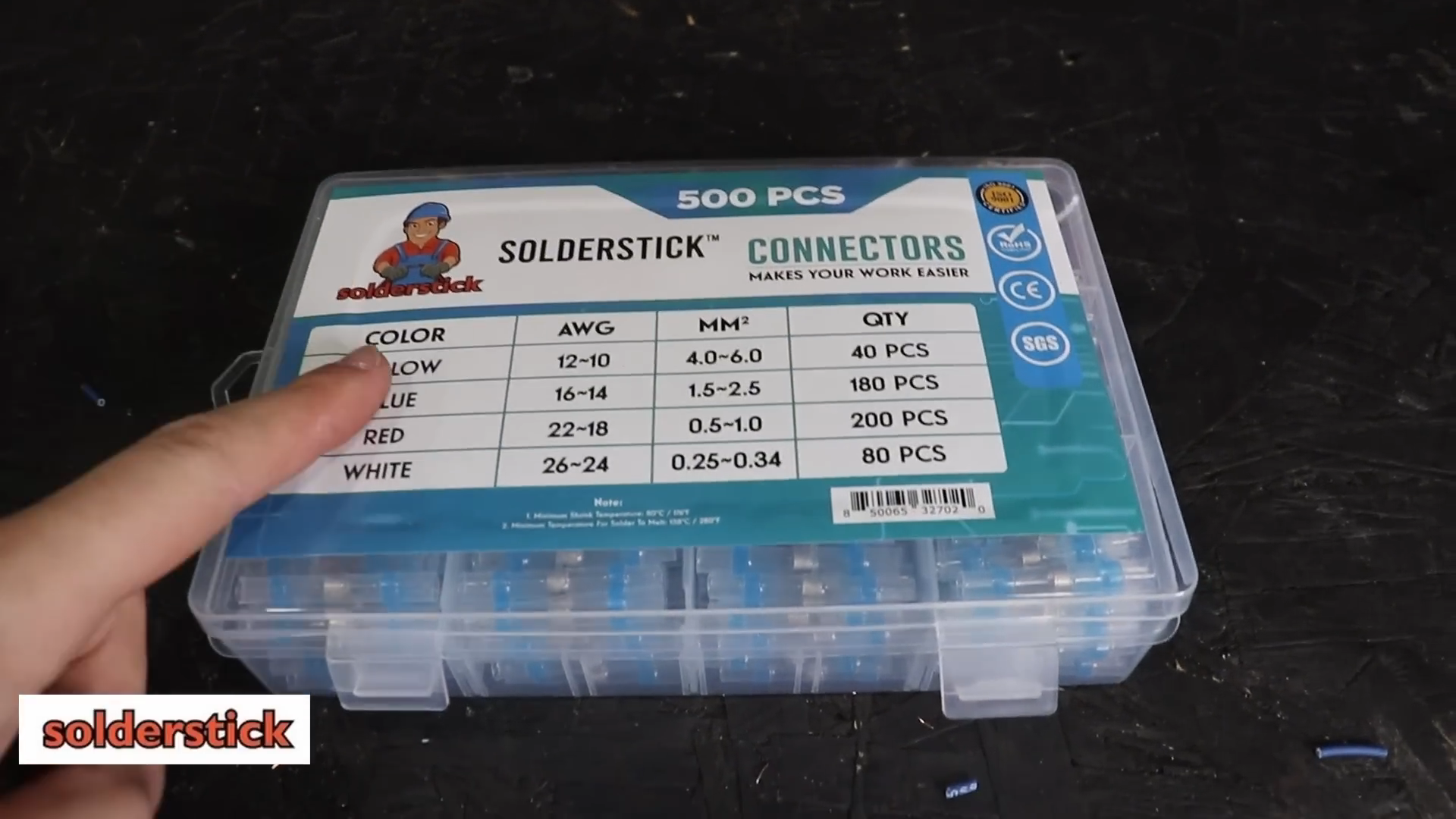

100-piece Professional Kit: Only $39.99 (normally $59.99)

200-piece Master Craftsman Kit: Just $59.99 (normally $99.99)

500-piece Ultimate DIY Bundle: An incredible $99.99 (normally $199.99)

That's professional-grade reliability for less than you'd spend on crimp connectors that are guaranteed to fail.

Think about it: What's the cost of one roadside breakdown? One embarrassing trailer light failure? One service call you have to make because your "permanent" repair didn't hold?

A single SolderStick kit pays for itself the first time it saves you from that humiliation.

But here's the catch: These prices won't last, and inventory is disappearing fast.

ZERO Risk - Try SolderStick 100% Risk-Free for 30 Days

I know what you're thinking. You've been burned before by products that promised the world and delivered disappointment.

That's exactly why SolderStick's creators are backing their connectors with an iron-clad, no-questions-asked, 30-day guarantee.

Here's the deal: Order your SolderStick kit today. Use them on your next wiring project. Test them yourself—submerge them in water, expose them to vibration, pull on them until your arms get tired.

If they don't exceed every expectation you have, simply contact SolderStick within 30 days for a full, prompt refund.

No hassle. No questions. No fine print.

You keep the connectors you've already used, and you get every penny back.

You literally have nothing to lose—and your reputation as a craftsman to gain.

The Choice That Will Define Your Next Decade

Right now, you're at a crossroads.

Path #1: Keep doing what you've always done. Keep using the same connectors that have let you down before. Keep making the same repairs that fail at the worst possible moments. Keep accepting "good enough" when you know you deserve better.

Path #2: Join the thousands of mechanics who've discovered what military and aerospace engineers have known for decades. Make connections that are stronger than the wire itself. Build a reputation based on work that never fails. Take pride in craftsmanship that stands the test of time.

The choice is yours.

But remember: This special pricing is strictly limited to current inventory.

Once these kits sell out—and based on current demand, that could happen within hours—you'll be back to waiting months for the next production run.

Don't let this opportunity slip away.

Click the button below to secure your SolderStick connectors at the lowest price they'll ever be offered:

Easy. Reliable. Permanent. Guaranteed.